Continuous monitoring system for the safe storage and use of hydrogen in hydrogen refuelling stations

Data

Acronym: LEAKWIT

Reference: CPP2021-008524

Partners: Instituto Tecnológico y de Energías Renovables, S.A (ITER), Vainsa Infraestructuras, S.L and Universitat Politécnica de Valéncia (UPV).

Duration: 2022-2025

Budget: 880,628.05 €

Co-Financing: Public-Private Collaboration 2021. State Plan for Scientific and Technical Research and Innovation 2021-2023. Ministry of Science and Innovation. Project CPP2021-008524 funded by MCIN/AEI/10.13039/501100011033 and by the European Union NextGenerationEU/PRTR.

Project overview

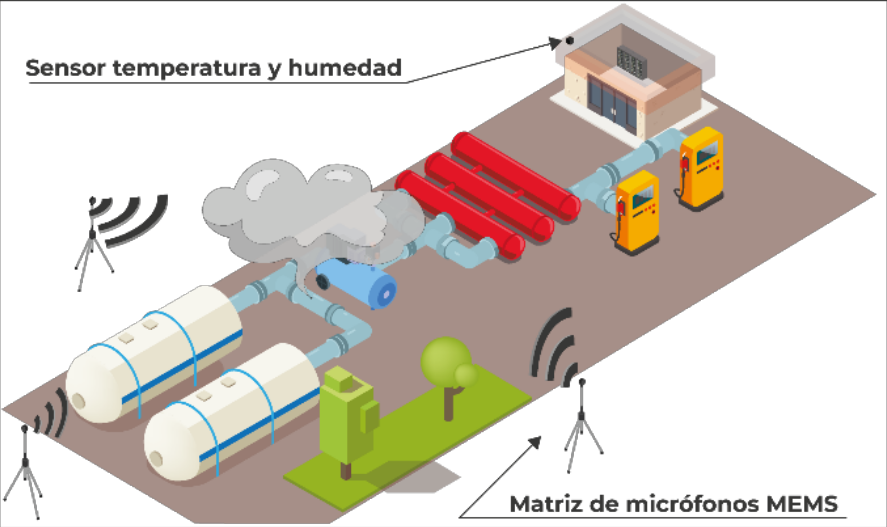

Hydrogen refuelling stations (HRS) are service stations that supply hydrogen for refuelling fuel cells. During refuelling, the hydrogen supplied from the storage tanks passes through a compressor, a heat exchanger, and then to the filling equipment. It is precisely during the storage stage where hydrogen presents the greatest challenges, the most notable being its tendency to explode when it mixes with oxygen suddenly: such as in a rupture of the storage tank or valve that causes a sudden release of hydrogen at high pressure.

Current techniques or systems for identifying leaks include electromechanical impedance, hydrogen-sensitive sensors, fibre optics, acoustic cameras, or acoustic sensors. Unfortunately, these systems are not capable of identifying leaks effectively and at low cost in real-time and continuously. In this context, there is a need to develop a system capable of detecting leaks quickly and effectively, with the ability to intervene before serious accidents occur and to reduce citizens’ safety concerns.

Consequently, the objective of the LEAKWIT project is to develop a novel comprehensive system for the detection and management of gas leaks in hydrogen refuelling stations, capable of:

- conduct leak detection in real-time and continuously;

- obtain the location and size of the leak in the main components of the HRS;

- provide a real-time risk analysis and management system.

The system to be developed will employ two independent levels of leak detection in order to reduce the number of false positives. The first level will be based on the use of acoustic sensors for the continuous monitoring of hydrogen storage tanks and pipes present in hydrogen refuelling stations. In this way, this first level of detection will have triangulation algorithms for the amplified acoustic signals to determine their location and a Neural Network capable of differentiating acoustic waves from leaks from those belonging to another nature. In the second level, the detected leak will be automatically introduced into a Digital Twin of the components that constitute the hydrogen refuelling station: storage tanks and pipes to perform a simulation with the aim of verifying whether the temperatures and pressures in the storage tanks, as well as the flow in the pipes, correspond with those recorded in-situ.

At the end of the project, the three partners of the Consortium, formed by the engineering group of the Multidisciplinary Mathematics University Institute (IMM) of the Polytechnic University of Valencia (UPV), Vainsa Infraestructuras, and ITER, will validate the LEAKWIT system in an operational environment.

As a final objective of the project, it is planned to commercialise the system as a service for HRS owners.

The LEAKWIT project (CPP2021-008524) is funded by the Ministry of Science and Innovation and the State Research Agency (10.13039/501100011033) and by the European Union within the framework of the EU Recovery Plan NextGenerationEU and the Spanish Recovery, Transformation and Resilience Plan (PRTR).

Links of interest: