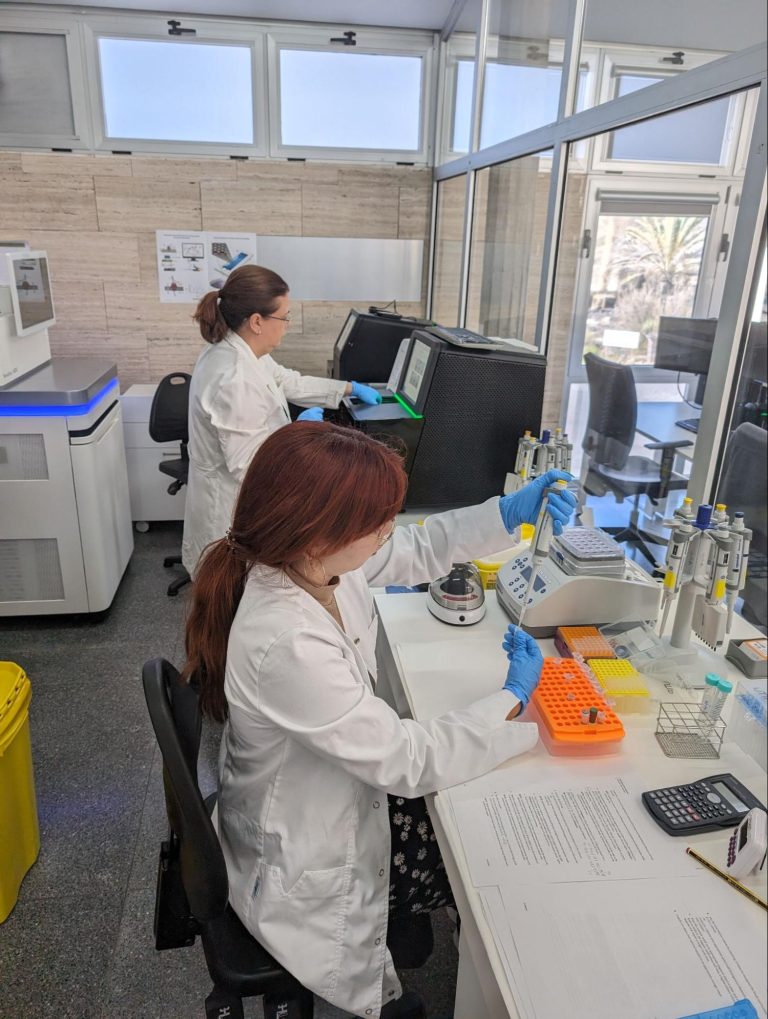

Either for specific final applications or as necessary during the realization of other projects, the Electronics Department has developed several electronic products. These products have been made from scratch, covering all phases from conception and design to prototype construction and manufacturing.

The specification is taken as a starting point and an electronic schematic is produced. Some parts may require simulation. If any part requires it or the circuit is simple, a prototype can be made with a PCB made ‘in situ’ or a drilling circuit. Generally, except in emergencies, printed circuit boards are ordered from the CAD-CAM design to an external company. SMT assembly for single units or small series is done by hand and depending on the quantity, the mode may vary. Although automatic machinery is available, it would only be used for large series.

The acquired know-how makes it possible to offer related services. The services include any of the phases separately or together from design to final production.

For example, the customer can order a printed circuit board from a schematic and assemble it on his own, or order a prototype, or a manufacturing. They can also order a proven circuit design and manufacture it themselves.

In short, the possibility is offered to those who do not have the electronic capacity at any of their levels to be able to materialize their ideas.

Electronic workshop services

While not a core activity, certain electronic workshop services or specific repairs could be performed. For example, electrical measurement and thermography services can be provided. Also automatic cutting and stripping of cables, as well as crimping of certain types of terminals.

The request for services shall be made through the section REQUEST, indicating the service requested, as well as the applicant’s details.

Links of interest: