A COVID-19 analysis device has been made available to La Candelaria University Hospital and visors for protective screens are being manufactured for healthcare personnel.

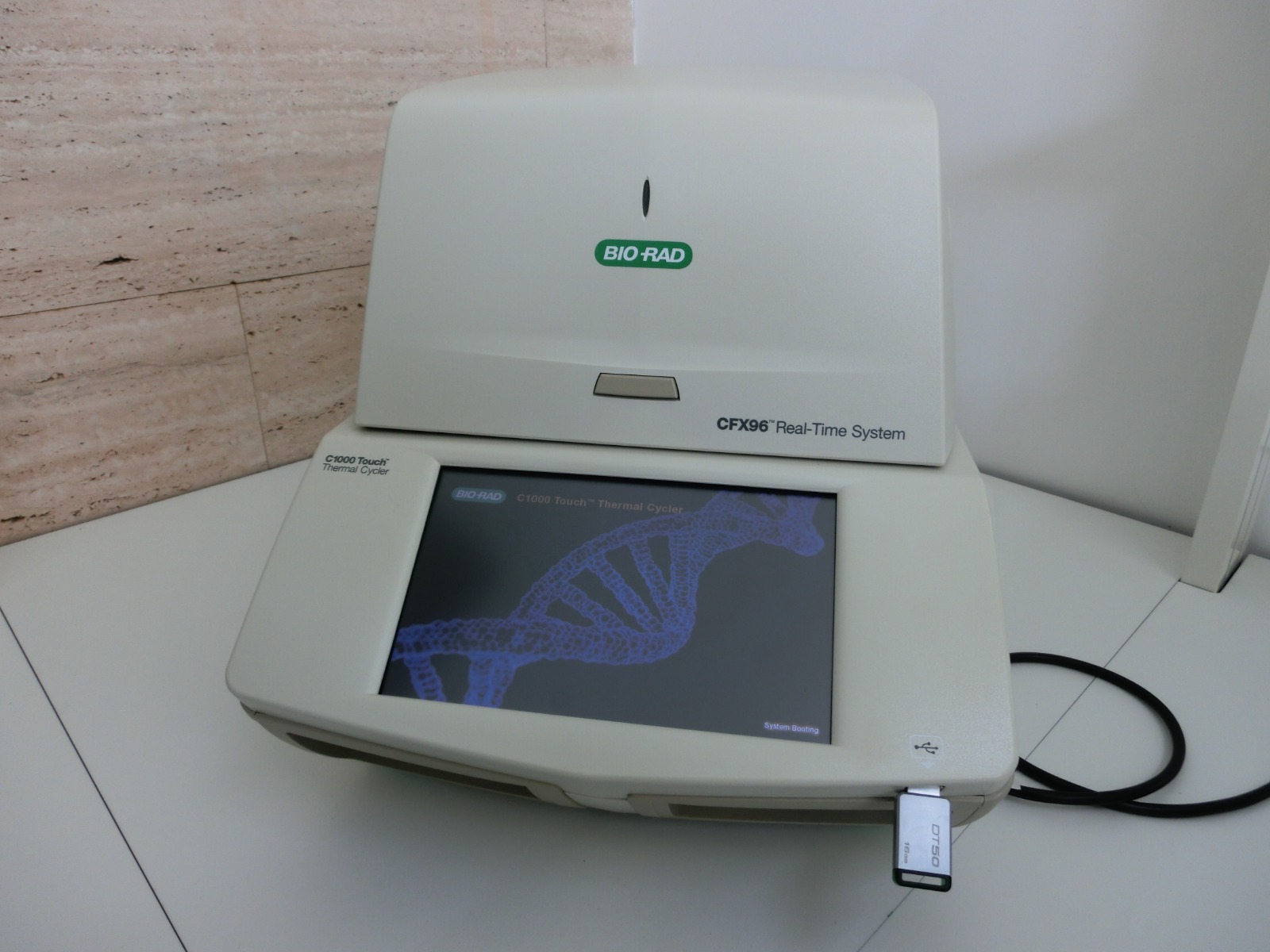

The Institute of Technology and Renewable Energies (ITER) has ceded a qPCR (Polymerase Chain Reaction) instrument that facilitates the diagnosis of COVID-19 cases to the Nuestra Señora de Candelaria University Hospital Complex (HUNSC, translated from Spanish). The aforementioned instrument, which was transferred on February 27, allows 50 tests per hour.

The qPCR equipment, which is commonly used in the ITER’s Genomics laboratory, is located in the laboratories of the hospital complex, and allows to know if a sample (generally collected through the nostrils, although it can also come from the mouth, from faeces or blood), contains the SARS-CoV-2 virus and determine the viral load of it. These two parameters are essential for the diagnosis and the measures that clinical professionals must take.

Likewise, during the last week, technical staff and researchers from the Genomics area of ITER itself, led by Dr. Carlos Flores, have joined the hospital’s laboratories, on a totally voluntary and disinterested basis.

The collaboration idea is to support the HUNSC Microbiology Service human team during the analysis process, with the aim of increasing the number of tests carried out daily and giving a break, as far as possible, to professionals who have been working on these tasks for weeks.

ITER staff that is collaborating with the HUNSC has extensive research experience in sample preparation procedures (extraction of viral RNA), the use of the required PCR techniques, automation robots, as well as the safe handling of the Personal Protective Equipment necessary to preserve their health.

The selection of these personnel has been made following a series of criteria: volunteerism, training, previous experience, availability of flexible hours, the possibility of undertaking physical isolation measures in their homes during rest periods, and the existence of contact with risk population in their homes (dependent people, children, young and old people with other risk factors).

Manufacture of protection screens for healthcare personnel

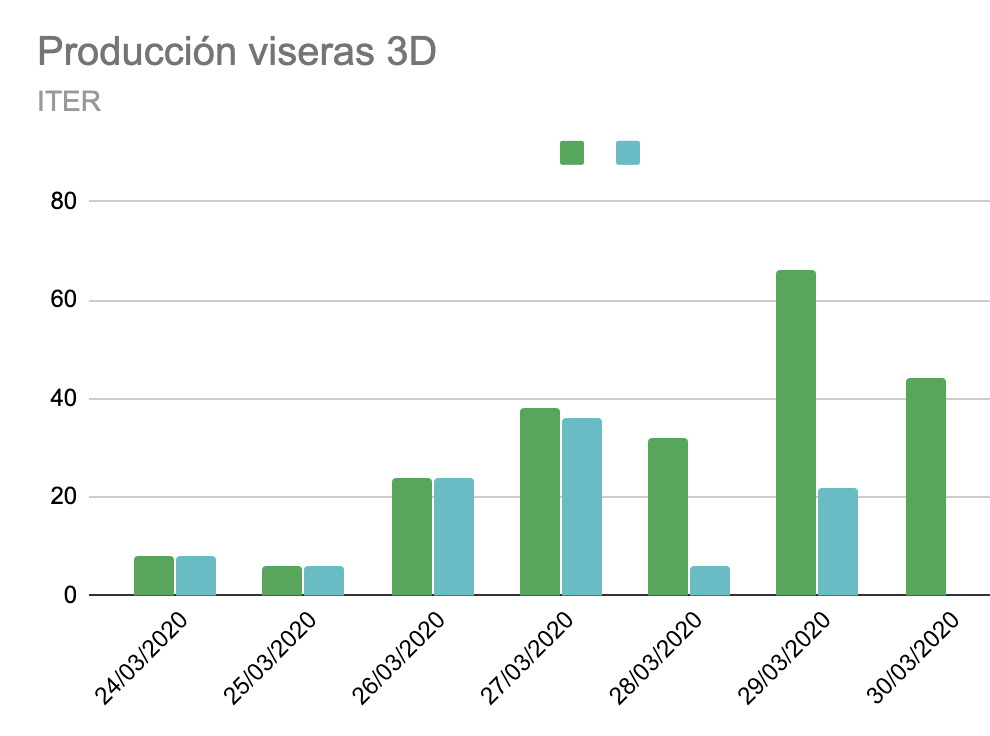

On the other hand, personnel from various ITER departments (Robotics, Electronics, Informatics, Renewable Energies and Environment) have started the manufacture of visors to carry protection screens in order to be used by health personnel during the crisis situation derived from the coronavirus .

Constituted in a work team, using four ITER 3D printers and three personal ones that these workers had at home, they got down to work.

During the first days, an average of 20 visors of the model validated by the sanitary experts were produced, currently and with all the printers configured and operating at full capacity, an average of 50 visors per day it’s being manufactured.

The pieces are created with filament -plastic thread necessary for 3D printing- that they had to urgently purchase to be able to manufacture. All the visors that are manufactured are delivered in a coordinated way to the distribution groups for their subsequent assembly and distribution at the collection points.

Furthermore, the working group that has been constituted at ITER is currently working on the design of an air pump to be used as an alternative in the construction of respirators. This pump is based on a design of parts and mechanisms to be 3D printed and other low cost and easily accessible materials. This work is being carried out in coordination with working groups at local and national level. Attached link to video and images.

If necessary, the prototype respirator parts proposed and agreed upon as accepted by the national health system will also begin to be produced by 3D printing for use, in addition to those already available in the system.

It should be noted that the work of this team began in an altruistic way, and with the support of the company itself, dependent on the Tenerife Island Council. These people became part of groups known as Coronavirus Makers, in which they detected what their work could be to help society in the face of this pandemic. Given the indications of the State and the Insular Institution to work from home, they considered that manufacture of screens was the most accessible and necessary work.

In addition, the working group that has been formed at ITER is currently working on the design of an air pump to be used as an alternative in the construction of respirators. This pump is based on a design of parts and mechanisms to be printed in 3D and other low-cost and easily accessible materials. This work is being done in coordination with working groups at local and national level. Attached is a link to video and images.

If necessary, we will also begin to produce, by 3D printing, the parts of the prototype ventilator that is proposed and agreed as the one accepted by the national health system for use as a complement to those already available in the system.

It should be noted that the work of this team began altruistically, and with the support of the company itself, which depends on the Cabildo of Tenerife. These people became part of groups known as Coronavirus Makers, in which they identified what their work could be to help society in the face of this pandemic. Given the indications of the State and the island institution to work from home, they considered screen manufacturing to be the most accessible and necessary work.