TALLER DE MODELADO

El ITER cuenta con un taller de modelado para la fabricación de las maquetas objeto de ensayo en el túnel de viento así como prototipos desarrollados en la empresa.

Capacidades

- Tecnología CAD/CAM: modelado tridimensional y confección de prototipos, moldes y utillajes diversos.

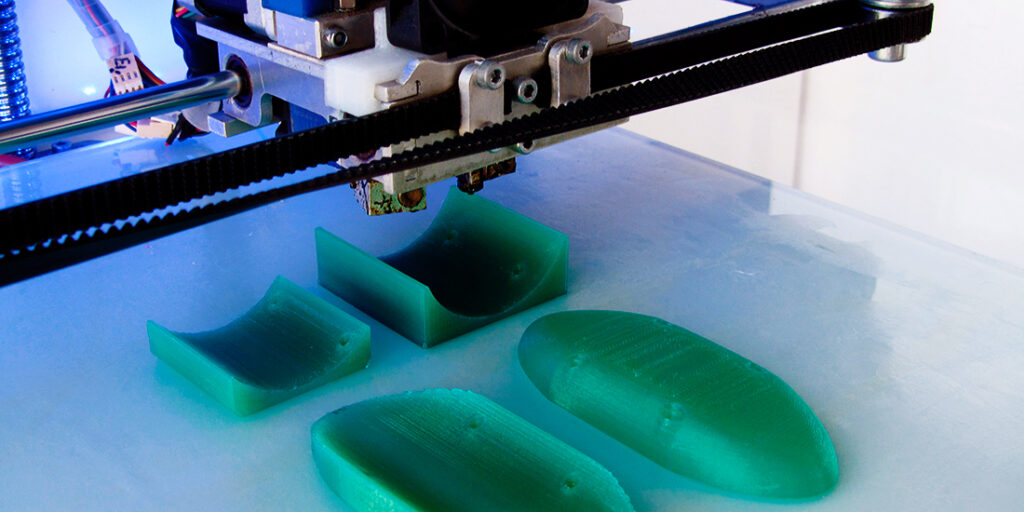

- Impresión 3D: tecnología de manufactura aditiva con materiales termofusibles, especialmente indicado en la confección de prototipos de pequeño tamaño.

- Fresadora CNC: empleada en la fabricación de útiles y prototipos en materiales de media/elevada resistencia tales como plásticos, maderas, aluminio, cobre, etc.

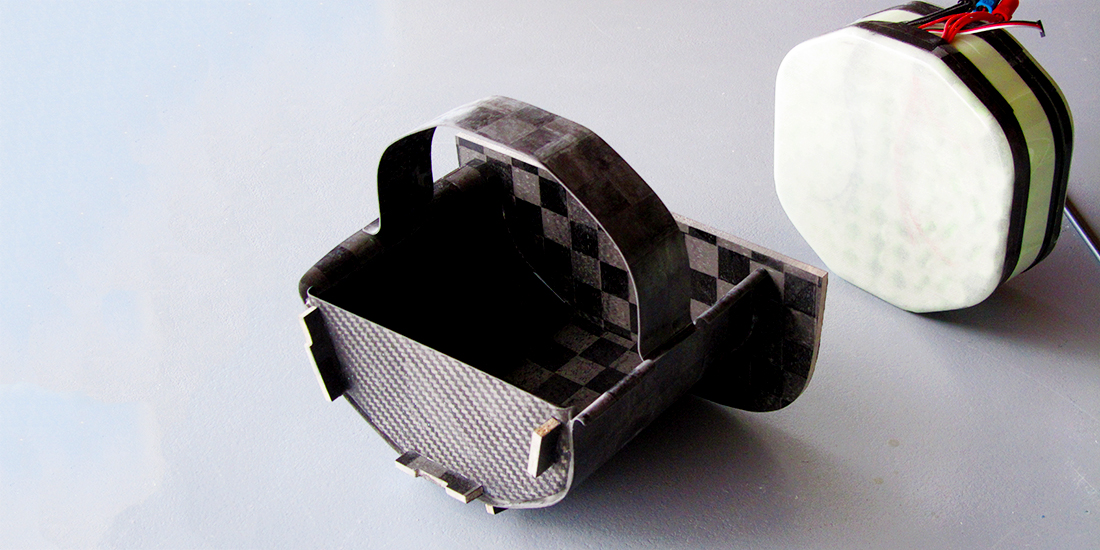

- Composites: unida a la capacidad de realizar utillajes con la tecnología CAD/CAM, el taller dispone de diversas herramientas para la confección de los útiles necesarios para la fabricación de piezas y moldes en la técnica de los composites, utilizando resinas de epoxi y poliéster con refuerzos de fibra de vidrio, carbono y kevlar.

El taller trabaja conjuntamente con el departamento de mantenimiento cuando los requerimientos sobrepasan las capacidades propias del taller de modelado, disponiendo de un taller de estructuras metálicas, taller de mecanizado, carpintería de aluminio y de madera dotados de profesionales de gran experiencia.

El taller trabaja conjuntamente con el departamento de mantenimiento cuando los requerimientos sobrepasan las capacidades propias del taller de modelado, disponiendo de un taller de estructuras metálicas, taller de mecanizado, carpintería de aluminio y de madera dotados de profesionales de gran experiencia.

Enlaces de interés: