Laboratorio de fotovoltaica – SiCell Lab

El Laboratorio de Fotovoltaica de ITER, conocido como SiCell Lab, es una infraestructura científico-tecnológica de vanguardia concebida para contribuir al desarrollo y fortalecimiento de nuevas técnicas de fabricación de células fotovoltaicas basadas en silicio cristalino y nuevos materiales. Sus dimensiones y el carácter modular le confieren flexibilidad y adaptabilidad a nuevos procesos, tales como la investigación con nuevos materiales para su uso dentro de las tecnologías fotovoltaicas.

Las principales líneas de investigación han sido desarrolladas en el campo de las células fotovoltaicas basadas en silicio cristalino. Además, se ha iniciado una nueva línea de investigación basada en el estudio de materiales emergentes y más concretamente aquellos, que por su estructura cristalina, reciben el calificativo de perovskitas.

Con el fin de poder evaluar y analizar cada una de las fases del proceso constructivo, el laboratorio se plantea como un sistema a escala para una línea de producción a nivel industrial, donde llevar a cabo los procesos de fabricación y caracterización de los dispositivos. La infraestructura cuenta con dos espacios de trabajo, uno destinado a la fabricación de células fotovoltaicas (Sala Blanca ISO7) y otro a la caracterización de las mismas.

Este laboratorio está siendo optimizado en el marco de marco del proyecto MACLAB-PV “Mejora de capacidades e infraestructuras de I+D+i en el sector de las energías renovables y la eficiencia energética de Canarias y Senegal”, co-financiado por el Programa INTERREG MAC 2014-2020.

Equipamiento del laboratorio:

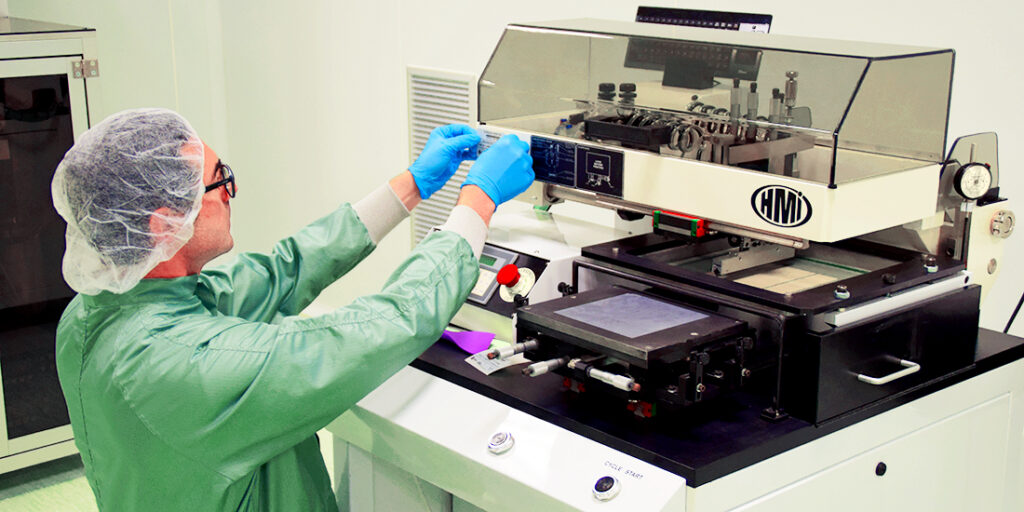

Laboratorio de Fabricación – Sala blanca

La sala blanca ISO 7 (clase 10.000) tiene una superficie total de 65m2 y cuenta con el siguiente equipamiento:

- Sistema para la limpieza y texturización de sustratos. Banco químico – Achiever, MEI.

- Baño de ultrasonidos. ULTRASONS-HD, JP Selecta.

- Producción y suministro de agua pura tipo II (E-POD) y agua ultra-pura tipo I (Q-POD). Milli Q-Integral 3, Millipore.

- Sistema de deposición Spin-On. Polos HD 300, SPS.

- Horno de difusión por proceso térmico rápido. TM 100BT, LPT THERMPROZESS.

- Horno de cadena de cocido. Hengli, Torrey Hills Technologies, LLC.

- Horno de mufla. CWF 11/13, Carbolite.

- Estufa de secado. Conterm 19, JP Selecta.

- Sistema PECVD de cámara abierta para deposición química en fase vapor. Vision 300 MK II, Advanced Vacuum.

- Sistema de serigrafiado para impresión de contactos metálicos. 485 – Screen Printer, HMI.

- Molino de tres rodillos. ESG65, Shanghai Espread.

Laboratorio de Caracterización

El laboratorio de caracterización tiene una superficie total de 110m2 y cuenta con el siguiente equipamiento:

- Sistema de Respuesta Espectral. PVE 300, Bentham.

- Sistema óptico Fluorímetro. FLUOROSENS M11, Gilden Photonics.

- Elipsómetro. ESM-300, J.A. Woollam.

- Equipo de medida del decaimiento de la fotocorriente por microondas (MWPCD). WT-2000PVN, Semilab.

- Sistema de caracterización de semiconductores. SCS-4200, Keithley.

- Kit láser pulsado con escáner de procesado 2D y componentes opto-mecánicos. Powerlase.

Equipamiento auxiliar

- Sistema de acondicionamiento y filtrado de aire.

- Sistema de contabilización de partículas.

- Sistema de circuito cerrado de agua con enfriadora.

- Sistema de recirculación de agua desionizada.

- Sistema de evacuación de líquidos corrosivos.

- Línea de distribución de aire comprimido.

- Línea de distribución de mezcla gas de Silano al 2% y Nitrógeno (gas cabinet).

- Línea de distribución de mezcla de gas oxígeno al 20% y tetrafluormetano.

- Línea de distribución de gas Nitrógeno de 99,9980 % (técnico).

- Línea de distribución de gas Nitrógeno de 99,9995 % (ultrapuro).

- Línea de distribución de gas Protóxido de nitrógeno.

- Línea de distribución de gas Amoniaco.

- Sistema de abatimiento de gases tóxicos.

- Sistema de extracción de gases de alta temperatura.

- Sistema de extracción de gases tóxicos.

Tour Virtual al Laboratorio de fotovoltaica – SiCell Lab

Conoce esta infraestructura científico-técnica del ITER gracias a esta herramienta didáctica virtual desarrollada en el marco del proyecto MACLAB-PV “Mejora de capacidades e infraestructuras de I+D+i en el sector de las energías renovables y la eficiencia energética de Canarias y Senegal”, co-financiado por el Programa INTERREG MAC 2014-2020.

Enlaces de interés: