Photovoltaic generation solution adaptable for use in buildings and distributed generation

Details

Acronym: AISOVOL2

Reference: RTC2019-006994-3

Partners: Instituto Tecnológico y de Energías Renovables (ITER) and Centro Nacional de Energías Renovables (CENER).

Duration: 01/06/2020 – 31/12/2023

Budget: 768.516,50 €

Co-Financing: Retos Colaboración 2019. Programa Estatal de I+D+i Orientada a los Retos de la Sociedad. Ministerio de Ciencia e Innovación.

Project overview

It is considered that the future of photovoltaic energy is their architectural integration, which today constitutes a growing market with an expected penetration of 13% by 2022. Thus, photovoltaics stands out as a technology that will play a key role in the urban and environmental development of cities, promoting the construction or adaptation of so-called almost zero energy buildings.

Taking into account this market trend and the objectives set in the energy sector, both national and European, it is developed the AISOVOL2 project, a photovoltaic generation solution adaptable for use in buildings and distributed generation. The aim of this project is to meet the demands of innovative photovoltaic solutions that allow a more intensive and multi-functional use of the available surface in buildings, achieving sustainable cities.

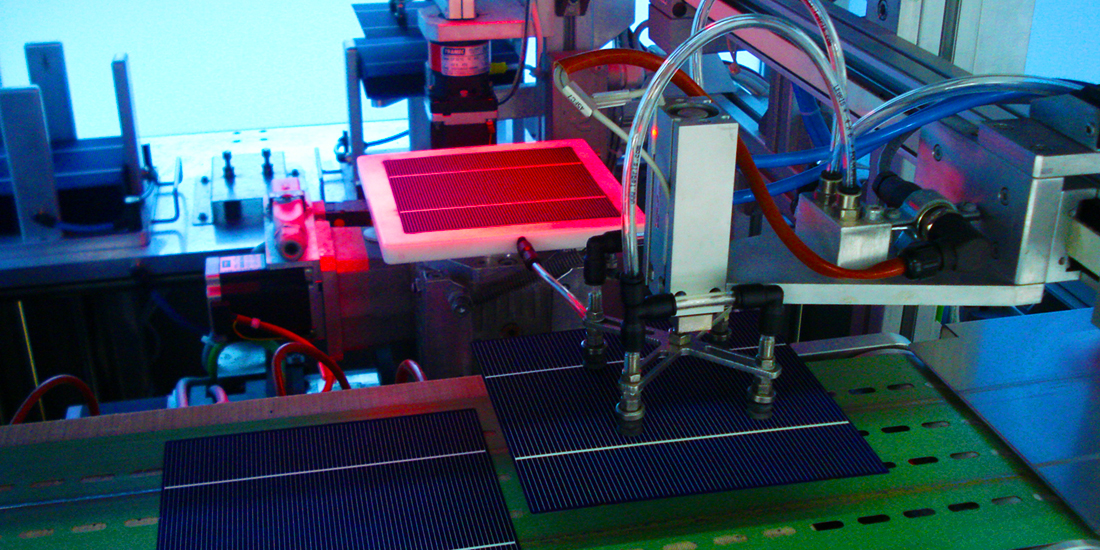

Its objective is the development and manufacture of an adaptable and multi-functional photovoltaic module, which increases the architectural resources available both for photovoltaic technology adapted in buildings and for technology integrated into the structure of the building itself, using cutting-edge materials and latest photovoltaic technology such as bi-facial cells. This will allow to evolve in the research of alternatives that satisfy the trends of the photovoltaic market and the requirements of professionals from the construction industry.

This endeavour also constitutes a continuation of the research line undertaken with the AISOVOL project. This project proposed the manufacture of a modular, integrable, and easily adaptable photovoltaic module for use as an architectural element by replacing some of the components that make up a conventional photovoltaic module. The most notable modification was the replacement of tempered glass by compact poly-carbonate.

Alternatives in the design of the photovoltaic module that make it possible to overcome the difficulties encountered during the first project, based on the experience acquired during its execution, are introduced in AISOVOL2. The alternative materials proposed retain the philosophy of the previous project in terms of the features of the photovoltaic module to be manufactured and give this proposal an innovative spirit, taking advantage of the development of new avant-garde materials specially designed for the photovoltaic sector and latest market trends such as the bi-facial technology.

It also includes conducting the test required to commercialise a product of this technology. Specifically, compliance with the standards for crystalline silicon photovoltaic modules established by IEC 61215 in terms of design qualification and approval will be verified. In this way, the viable products obtained with this experience will be suitable for commercialisation.

Moreover, the project is completed with the design and manufacture of a monitoring and recording system for the characterisation and qualification of photovoltaic modules through field tests. This system will complement the work developed in the previous AISOVOL project, where perform field test was not considered, and make it possible to provide comparative information on the operation between the two designs.

In the same way, it will allow to carry out a study of the performance of bi-facial modules to evaluate the influence of certain installation parameters, such as mounting height, inclination or ground reflectivity. Thus, the objective of the monitoring system is to obtain information on the real module performance during day-to-day operation with changing irradiance and temperature conditions, due to these conditions are usually very different from those established in the measurement standards for this technology.

In that sense, thanks to the continuous determination of the I-V curve that this system enables, various types of problems can be detected in the panel elements, such as an excess internal resistance or a group of faulty solar cells.