Design & production of electronic circuits

Services for developing and producing electronic circuits

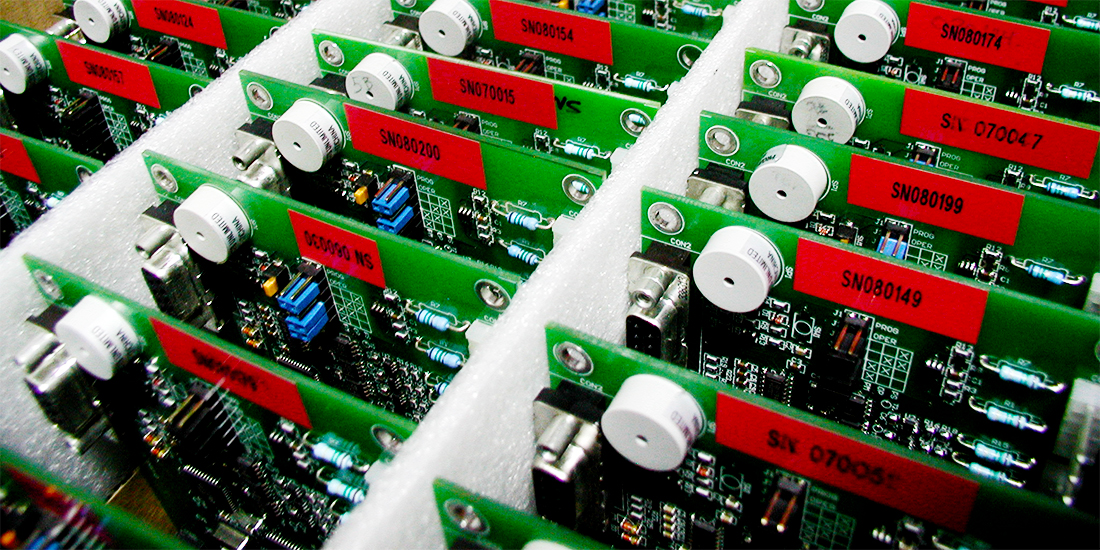

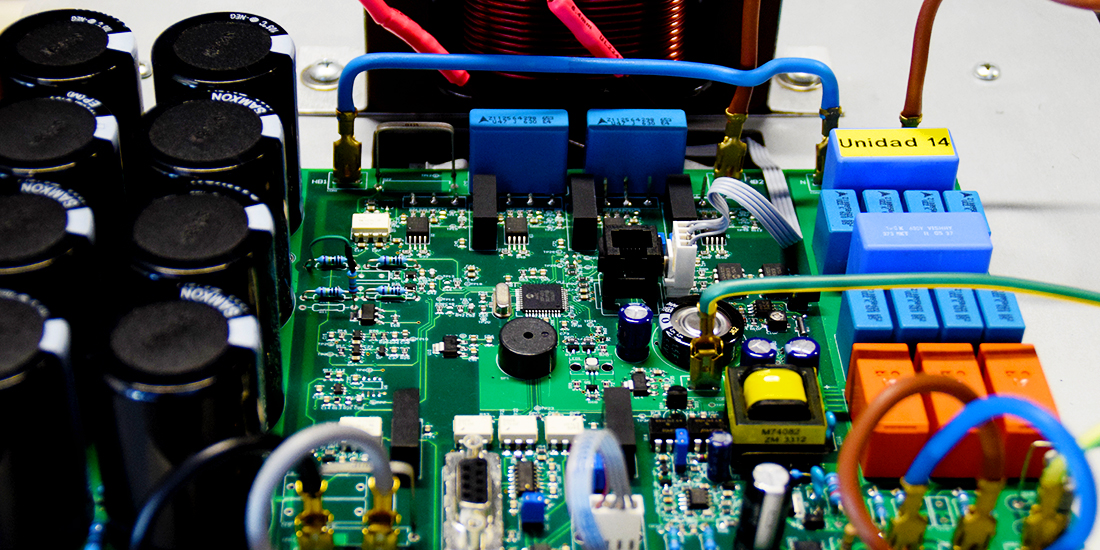

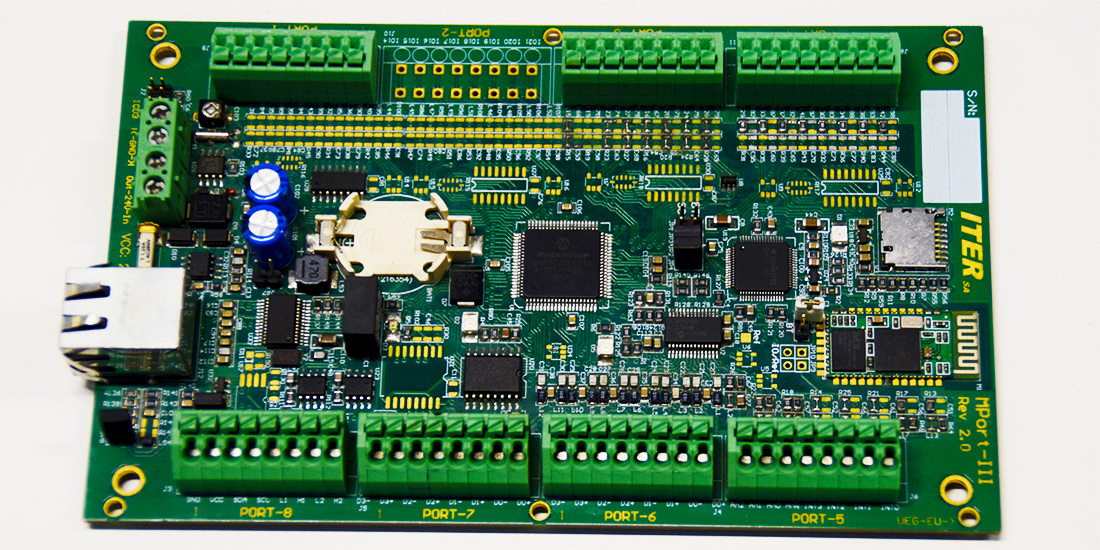

ITER’s electronics department has developed a number of electronic products, both for specific end uses and as components for other projects. ITER makes them from scratch, from conception and design to prototype construction and manufacturing.

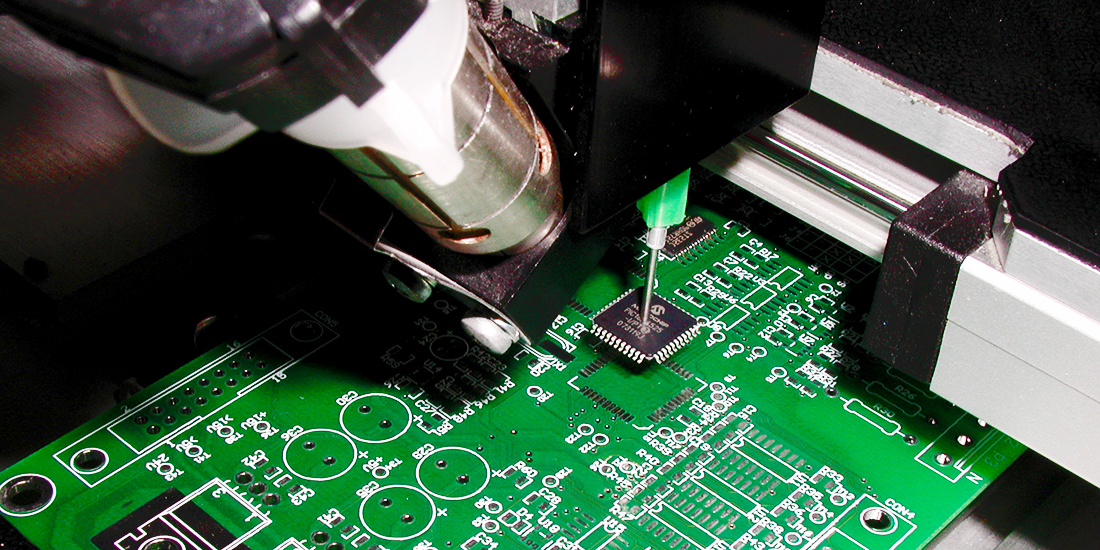

The starting point of the process is the product specification, then a circuit plan is drawn up. Some parts may require simulation. If any part does require simulation, or the circuit is simple, a printed board prototype is made in situ or a perforated circuit board is used. Except in urgent cases, the circuit boards are generally commissioned from an external supplier, based on the CAD-CAM design. The SMT assembly for single units or small series is done by hand; the means of doing this depends on the number produced. Although there is automatic machinery on site, it would be used only for larger volumes.

Related services are also offered, based on the know-how acquired at ITER in this area. These services can be for any individual stage of the process, or for the full process, from design to final production.

For example, clients may order a printed circuit board from a plan and assemble it themselves; or order a prototype or a production run; or order a tested circuit design and manufacture the board themselves.

In short, we offer options for whoever does not have electronic capabilities at any given level, to realise their ideas.

Electronic workshop services

Although not a core activity for ITER, certain electronic workshop activities or specific repairs are possible. For example, electrical measurements and thermography services. Automatic wire cutting and peeling, and certain types of crimping, are also available.

Service requests are to be made via the APPLICATION section at the sidebar, indicating the service required and the details of the applicant.